Description

TPU potable water hoses is made from extruded thermoplastic polyether based polyurethane (TPU) with excellent wear & tear properties. The reinforcement is made from circular woven filament polyester yarn. The “extrusion through the weave” production method gives a very strong bonding between cover and lining as well as firmly encapsulating the woven polyester.

The hose has the following potable water certificatons:

Meet NSF 61 standard, USA

Applications

- Municipal

Emergency water supply pipeline by-pass waste transfer testing/flushing. Water mains

delivery from water tanker construction sewer and water treatment municipal fire services.

- Marine

Potable water to ships/boats cargo loading/unloading supply ship to offshore facilities.

- Industrial

Potable water for food processing high flow dewatering mobile high volume air conditioning

(HVAC) liquid and powder foodstuffs, slurry pumping beer/wine, transfer loading/unloading from truck or rail car industrial fire services.

- Military

Potable water transfer.

Features

- The TPU-material used in potable water hoses has a high resistance against commonly used chemicals and degradations due to UV radiation. Also, the excellent abrasion resistance of the TPU material enables the use of very thin and lightweight hoses with large diameters to be quickly and easily deployed in disaster areas without risk of damage to the hoses.

- The circular weaving of the filament polyester yarn ensures interlocking of the reinforcing yarns and increases both tensile strength and pressure rating. The interlocking weave ensures that the extension in length does not exceed 2% when pulled or pressurized. This keeps “snaking” of the hose at a minimum.

- TPU potable water hoses can operate in a temperature range from -50 C deg to +75 C deg and can withstand intermittent use up to +80 C deg.

Comparable to

- Aquaman of Mandals

- Super Aquaduct of Angus

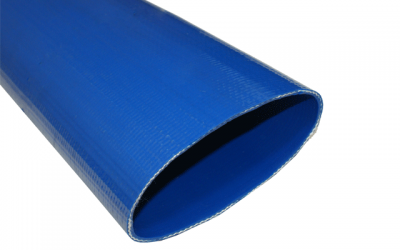

Color

- Blue (Other color available of request)

| Size | Proof Test Pressure | Bursting Pressure | Weight | Wall Thickness |

| PSI | PSI | LBS (Per 50 inch) | Inch | |

| 1 1/2″ | 220 | 650 | 12 | 0.08 |

| 2″ | 220 | 650 | 15 | 0.08 |

| 2 1/2″ | 200 | 600 | 20 | 0.09 |

| 3″ | 200 | 600 | 25 | 0.09 |

| 4″ | 200 | 600 | 38 | 0.12 |

| 5″ | 200 | 600 | 50 | 0.13 |

| 6″ | 200 | 600 | 60 | 0.14 |

| 8″ | 150 | 450 | 80 | 0.16 |

| 10″ | 150 | 450 | 110 | 0.17 |

| 12″ | 150 | 450 | 130 | 0.18 |