Need advice ?

Leave a request and we will call You back

- 1

- 2

G2 offers a wide range of world class lay flat hose products for applications such as – but not limited to – frac water transfer; irrigation; drinking water and wells; dewatering ; slurry; and fire protection etc.

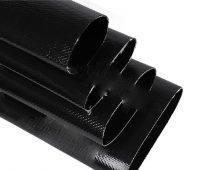

Asoe Longman Series Hoses shall be made from 100% high tenacity synthetic yarn circular woven and completely, protected and locked-in by tough highly resistant synthetic nitrile rubber, forming a single homogenous construction without the use of glues or adhesives of any type. The hose is intended for transfer of large volumes of liquid at higher than normal working pressures while at the same time being lightweight and easy to deploy. More information, please check Longman 450, Longman 600, Longman Supply, Longman Attack etc.

Asoe Longman Series Hoses shall be made from 100% high tenacity synthetic yarn circular woven and completely, protected and locked-in by tough highly resistant synthetic nitrile rubber, forming a single homogenous construction without the use of glues or adhesives of any type. The hose is intended for transfer of large volumes of liquid at higher than normal working pressures while at the same time being lightweight and easy to deploy. More information, please check Longman 450, Longman 600, Longman Supply, Longman Attack etc. Asoe Mileflex is made from thermoplastic polyether based polyurethane (TPU) extruded through a circular woven jacket made from high tenacity filament polyester yarn. The hose is intended for transfer of large volumes of liquid at higher than normal working pressures while at the same time being lightweight and easy to deploy.

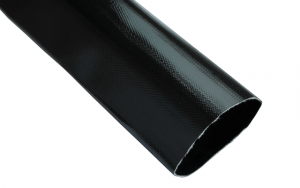

Asoe Mileflex is made from thermoplastic polyether based polyurethane (TPU) extruded through a circular woven jacket made from high tenacity filament polyester yarn. The hose is intended for transfer of large volumes of liquid at higher than normal working pressures while at the same time being lightweight and easy to deploy. Asoe Oilvey Oil Transfer Hoses are used for for transfer of oil and other flammable liquids. The hose is made from thermoplastic polyether based polyurethane (TPU) extruded through a circular woven jacket made from high tenacity filament polyester yarn. Anti static wires are used to remove static electricity. More information please check Oilvey 10 and Oilvey 20.

Asoe Oilvey Oil Transfer Hoses are used for for transfer of oil and other flammable liquids. The hose is made from thermoplastic polyether based polyurethane (TPU) extruded through a circular woven jacket made from high tenacity filament polyester yarn. Anti static wires are used to remove static electricity. More information please check Oilvey 10 and Oilvey 20. Welline was designed with this extreme tensile stress and abrasion in mind. Welline PU hoses are designed for well riser. More

Welline was designed with this extreme tensile stress and abrasion in mind. Welline PU hoses are designed for well riser. More Manureflow was designed with this extreme tensile stress and abrasion in mind. The TPU cover has abrasion resistance 4 – 5 times that of commonly used rubber. The tensile strength has been substansially increased to withstand the pull forces. More

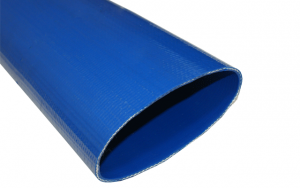

Manureflow was designed with this extreme tensile stress and abrasion in mind. The TPU cover has abrasion resistance 4 – 5 times that of commonly used rubber. The tensile strength has been substansially increased to withstand the pull forces. More NSF Water Hose is made from extruded thermoplastic polyether based polyurethane (TPU) with excellent wear & tear properties. The reinforcement is made from circular woven filament polyester yarn. The “extrusion through the weave” production method gives a very strong bonding between cover and lining as well as firmly encapsulating the woven polyester.

NSF Water Hose is made from extruded thermoplastic polyether based polyurethane (TPU) with excellent wear & tear properties. The reinforcement is made from circular woven filament polyester yarn. The “extrusion through the weave” production method gives a very strong bonding between cover and lining as well as firmly encapsulating the woven polyester.